The NISARGRUNA – Repaying Nature’s Loan

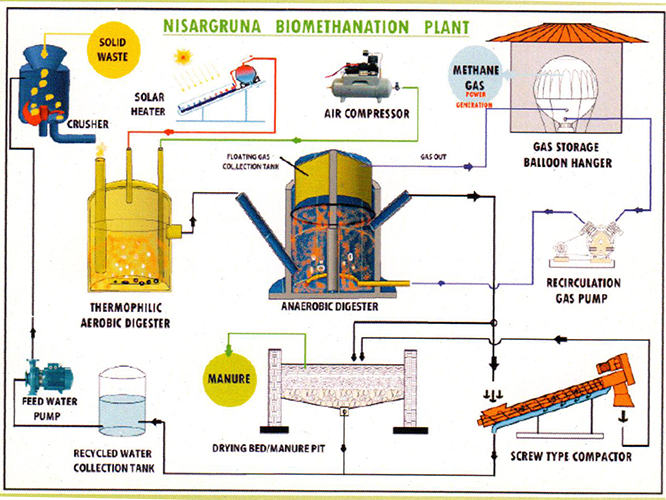

BARC’s NISARGRUNA plant for solid waste management offers a “Zero garbage, Zero effluent” method for waste management.

Waste disposal is one of the major problems being faced by all nations across the world. By 2047, it is expected that 1,400 sq. km. of landfill area would be required for dumping India’s increasing volumes of municipal solid waste; this space is roughly equal to the combined area of three out of top five most populous cities in India: Hyderabad, Mumbai and Chennai.

Nisargruna Process

Urban areas in India generate more than 143,000 tons of MSW per day of which over 70% is disposed of unsorted and untreated in open landfills (CPCB, 2015), leading to public health and environmental hazards.

The waste resources which can be processed using Nisargruna Biogas plant include biodegradable kitchen waste, paper waste, green waste, leaf litter and animal remains in abattoirs.

The waste resources which can be processed using Nisargruna Biogas plant include biodegradable kitchen waste, paper waste, green waste, leaf litter and animal remains in abattoirs.

Applications

The Bio gas plants are useful for Municipal Corporations, Hospitals, Hotels, Housing Societies, Govt. Establishments, Abattoirs, Nagar Palika, Grampanchayat and Farmers.

Requirement for the plant

• Segregated waste or facility for segregation of waste

• Adequate water requirement 60% of the water is recycled

• Adequate electricity arrangement for running of the plant

• Adequate security arrangement to protect plant and the process

• Segregated waste should be quickly processed to avoid rotting of waste

• Requirement may slightly vary depending on the type of waste and size of the plant

• Plant operates on biological activity of the microorganism in predigester and digesters therefore it takes some time for microorganisms to sustain.

• Adequate water requirement 60% of the water is recycled

• Adequate electricity arrangement for running of the plant

• Adequate security arrangement to protect plant and the process

• Segregated waste should be quickly processed to avoid rotting of waste

• Requirement may slightly vary depending on the type of waste and size of the plant

• Plant operates on biological activity of the microorganism in predigester and digesters therefore it takes some time for microorganisms to sustain.

The Process

The organically rich bio-degradable portion of solid waste is mixed with recycled water to form slurry. The slurry is then aerobically digested in pre-digester, where organic matter is converted to organic acids. The predigestion is accentuated by addition of hot water and intermittent aeration. Pre-digestion and temperature rises to 40°C by itself. Hot water obtained using solar energy is added to raise this temperature to 50°C. If sunlight is not sufficient especially during winter, provision can be made to use part of the biogas generated to heat the required quantity of hot water using methane stoves. The smaller molecules like proteins and simple carbohydrates are degraded during predigestion. The pH of the feed slurry to pre-digester is around 7-8. The retention time (hydraulic retention time) of 4 days is maintained in the pre digester. After the pre-digestion the pH reduces to 4-5. The pre-digester slurry is further digested under anaerobic conditions for about 15 days. The process of methanogenesis takes place in this digester. Methane and carbon dioxide are the terminal products of this process.

Processable Waste

Biodegradable wastes that can be processed in a NISARGRUNA plant include:

- Food waste from households, restaurants and industrial canteens

- Vegetable wastes from vegetable markets and kitchens

- Shredded paper

- Abattoir waste, especially cattle intestinal materials

- Cattle dung and night soil

- Green lawn cuttings, algae/plant material removed from water bodies like lakes, rivers or wells

- Green agro wastes (should be finely chopped before processing)

- The straw and sugarcane bagasse can be processed but only if effective grinding is available.

- These materials will have to be chopped very finely before processing

- Food waste from households, restaurants and industrial canteens

- Vegetable wastes from vegetable markets and kitchens

- Shredded paper

- Abattoir waste, especially cattle intestinal materials

- Cattle dung and night soil

- Green lawn cuttings, algae/plant material removed from water bodies like lakes, rivers or wells

- Green agro wastes (should be finely chopped before processing)

- The straw and sugarcane bagasse can be processed but only if effective grinding is available.

- These materials will have to be chopped very finely before processing

Non-Processable Waste

wastes that cannot be processed in a NISARGRUNA plant include:

- Coconut & Egg shells

- Coconut choir

- Feather

- Hair

- Green twigs

- Wood

- Coconut & Egg shells

- Coconut choir

- Feather

- Hair

- Green twigs

- Wood