Bio Digester Technology

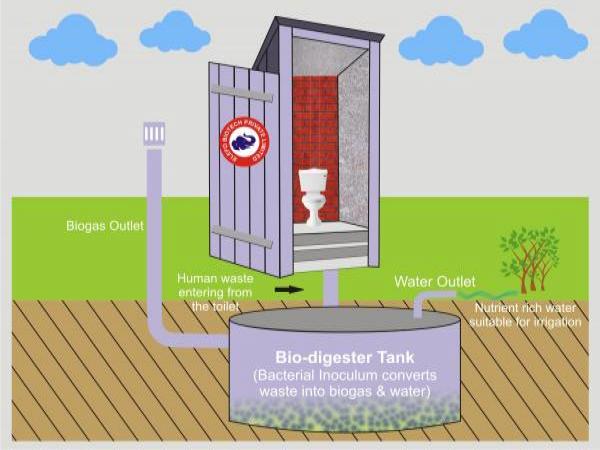

The Bio Digester is an innovative technology that disposes human waste in an eco-friendly manner. Here bacterial consortium degrades night soil and produces colourless, odourless fertile water and biogas.

Water recycled is clear and odourless. It is full of nutrients and minerals and is good for irrigation purposes, maintaining gardens, lawns etc. This unique bacterium multiplies on its own in anaerobic conditions which is present in the Bio digester tank which can be made of Mild Steel/ FRP/ Bricks/RCC.

These toilets installed with Bio digesters function efficiently at sub-zero to 55 Degree Centrigade. The smell of night soil and the disease causing organisms in it along with the solid matter is eliminated. On dry weight basis 90% of the solid waste is reduced.

Bio-Digesters require no sewage-line connection and are independent of any conventional energy requirement. The gaseous effluent (methane) is either continuously let off into the atmosphere or can be collected to be used for various energy incentive activities like generating electricity, water and room heating.

The dimensions and internal design varies with no. of users, water availability and geo-climatic conditions.

- Organic waste reduction > 90%

- Pathogen reduction > 90%

- Effluent water recycle

- Environment friendly

- Cost Effective

- Maintenance free

- Suitable for any geo-climatic condition

- Complete elimination of human scavenging

- Pathogen reduction > 90%

- Effluent water recycle

- Environment friendly

- Cost Effective

- Maintenance free

- Suitable for any geo-climatic condition

- Complete elimination of human scavenging

Low volume (Bio-digester size is 1/3 to 1/10 th of septic tank)

No foul smell

No cleaning required throughout its life hence eliminating manual scavenging

Lower cost

Water is recyclable

No foul smell

No cleaning required throughout its life hence eliminating manual scavenging

Lower cost

Water is recyclable

Ideal for single house/ multiple houses/ colonies

Mobile and stationary toilets in Urban areas

On-board treatment of human waste by Indian Railways

To be used in congested areas/ slums

Can be used for sewage treatment in all geo-climatic conditions in the country

Mobile and stationary toilets in Urban areas

On-board treatment of human waste by Indian Railways

To be used in congested areas/ slums

Can be used for sewage treatment in all geo-climatic conditions in the country

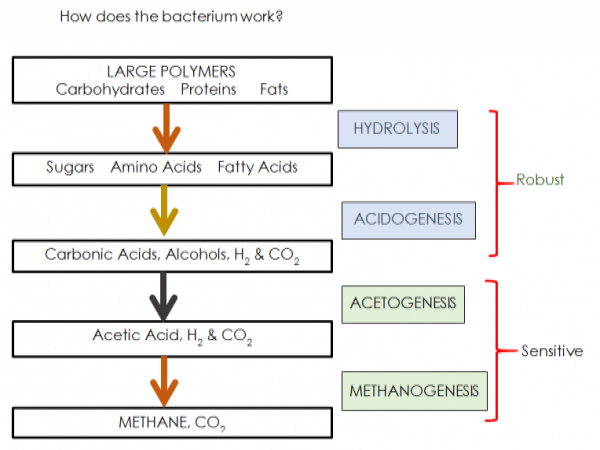

How does the bacterium work?

- Methanogenesis – It is a slow process during which it needs to be guaranteed that quantity of acetic acid generated does not exceed its utilisation . This can be ensured by either controlling the quantity of feed material (human waste / polymer) or by increasing the number of methanogens or their activity. Otherwise, accumulation of acids will lead to pH fall and process failure.

- Accumulation of higher fatty acids also need to be controlled otherwise besides contributing for fall in pH, they may be toxic to different groups of bacteria responsible for fermentation of the waste.

- Accumulation of higher fatty acids also need to be controlled otherwise besides contributing for fall in pH, they may be toxic to different groups of bacteria responsible for fermentation of the waste.

Why is it a win-win technology?

1. The treatment system works in all temperature ranges and geographical conditions of the country like high altitude areas, glaciers, desert, plains and islands.

2. Technology also works in mobile systems like Indian Railways,boats and temporary and make shift toilets

3. Bacteria addition is required only once in the life time.

4. The organic matter (human waste) is reduced (converted to gas to the extent of 90%).

5. Effluent & gas is free from any odour.

6. System does not require any cleaning throughout the life and no other maintenance.

7. No need of power / electricity.

8. Pathogens are inactivated (more than 90%).

9. Cost effective and space saving as the volume of fermenter is very low.

10. Use of toilet cleaning agents permitted.

11. Effluent is environment friendly.

12. Requirement of water for cleaning the toilet is minimal as P-trap can be avoided. Since water seal has been provided in the bio-digester itself.

13. Effluent can be used for cleaning the toilet pan or irrigation or may be discharged openly.

2. Technology also works in mobile systems like Indian Railways,boats and temporary and make shift toilets

3. Bacteria addition is required only once in the life time.

4. The organic matter (human waste) is reduced (converted to gas to the extent of 90%).

5. Effluent & gas is free from any odour.

6. System does not require any cleaning throughout the life and no other maintenance.

7. No need of power / electricity.

8. Pathogens are inactivated (more than 90%).

9. Cost effective and space saving as the volume of fermenter is very low.

10. Use of toilet cleaning agents permitted.

11. Effluent is environment friendly.

12. Requirement of water for cleaning the toilet is minimal as P-trap can be avoided. Since water seal has been provided in the bio-digester itself.

13. Effluent can be used for cleaning the toilet pan or irrigation or may be discharged openly.